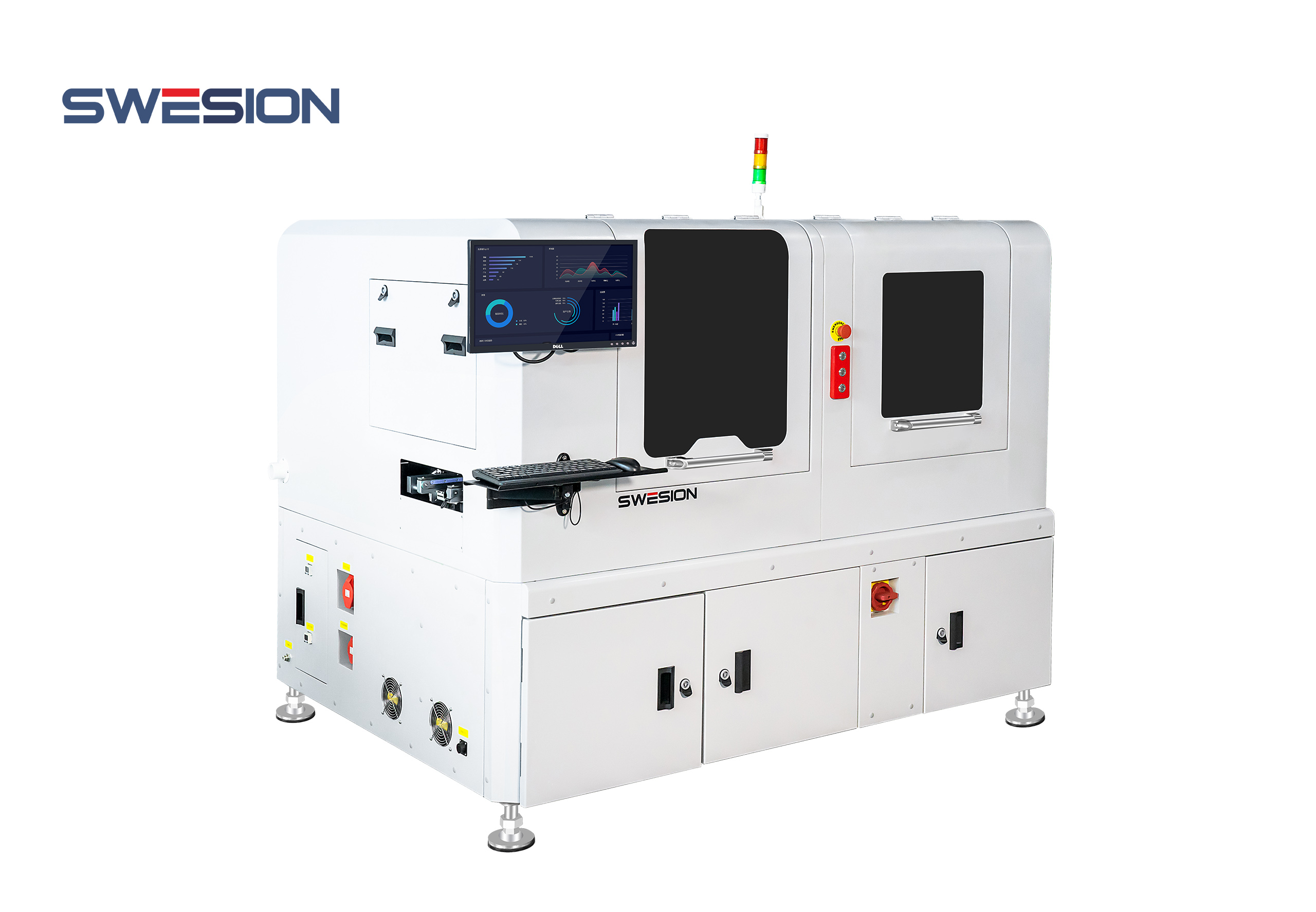

S400 Inline Multi-fuctional Fully Auto Depaneling Machine

S400 Inline Multi-fuctional Fully Auto Depaneling Machine

1. Multi-fuctional: Auto Feeding PCB, Depaneling, Put the PCBAs into Tray, Stacking Full Tray,Unloading Full tray

2. Features

- The design of the upper and lower dual worktables reduces the volume of the machine itself, which is beneficial for line body planning. It can perform picking/placing materials and cutting operations simultaneously, enhancing the overall economic value.

- The high – speed pick – and – place system is inspired by chip mounters and is a patent of our company. It can accurately, effectively and safely place the cut finished products into TRAYs in an orderly manner. It solves the problem for products such as chips, modules, and precision cutting products in the current depaneling industry to directly enter unmanned cutting production. Customers of this pick – and – place system can customize a multi – head pick – and – place system according to their production needs.

- The cutting edge inspection is completed by a visual inspection system. It detects and edits the cutting quality of the PCB edge. The camera module can detect whether there are burrs on the appearance of the PCBA, and supports data upload to MES for traceability.

- It efficiently absorbs dust, ensuring product cleanliness and machine tidiness, and perfectly adapts to production in a dust – free workshop (Class 7 cleanroom).

- It pioneered the automatic supply of TRAY trays for picking and placing. It can also supply hard TRAY trays, solving the problem of manual board collection still required in online depaneling.

- When the cutting tool reaches its preset cutting life or the tool detection system identifies that the tool needs to be replaced due to special circumstances, the system will automatically replace it with a new tool and quickly resume production within the shortest time.

| NO. | Item | Specifications |

| 1 | Working Area | 280*250mm, 350*300mm |

| 400*350mm, 600*400mm | ||

| (Customize is available) | ||

| 2 | Working Tables | 2 WorkingTables |

| 3 | PCB Thickness | 0.5mm~3mm |

| 4 | Positional Accuracy/Repeat ability accuracy | 士0.01mm |

| 5 | Cutting Accuracy | ±0.05mm |

| 6 | Cutting Speed | 0-100mm/s |

| 7 | Spindle System | High speed ESD certified spindle |

| 8 | Max. Speed | 80000rpm |

| 9 | Strengthening of PCB fixation(optional) | Vacuum absorbing or clamp |

| 10 | Working Table Output Mode | Synchronous belt+motor |

| 11 | Feeding track width adjust | Screw + motor or cylinder |

| 12 | Transfer Direction | From left to right |

| 13 | Feeding Methods | Belt+Motor |

| 14 | Discharging Method | Guide Rail |

| 15 | Dust collection system | Vacuum Cleaning System |

| 16 | Vacuum cleaner power | 5P |

| 17 | Filtration | External dust removal box |

| 18 | Cleaner Mode | Up/Down vacuum cleaner |

| 19 | Control system | Windows10 |

| 20 | Software Control Mode | PC control |

| 21 | Programming Mode | Visual alignment |

| 22 | Alarm Warning Tricolor light | Yes |

| 23 | Failure Alarm | Yes |

| 24 | Password Protection | Yes |

| 25 | Safety Door | Yes |

| 26 | Milling Cutter Change | 3 PCS (auto milling cutter changing) |

| 27 | Route Bit Diameter | 0.8~3MM |

| 28 | PCB Positioning and Adjustment Methods | Special fixture positioning |

| 29 | PCB Reinforced Fixation | Special fixture positioning |

| 30 | PCB Pick and Place | Independent high speed vacuum material handling arm |

| 31 | Automatically place product onto the fixture or track | Available |

| 32 | Trouble Shooting | Automatic alarm manual maintenance |

| 33 | Dimensions | 1950(L)*1550(W)*1600(H)mm+310mm(310mm Tricolor light) |

| 34 | Weight | 1200Kg |

| 35 | Power Supply | 3φ, AC380V 50HZ |

| 36 | Power Consumption | 13KW |

| 37 | Air | Clean, dry compressed air |

| 38 | Compressed Air | 0.5~0.7MPa |

| 39 | Temperature Range | 10~35℃ |

| 40 | TRAY Max. Size | 350*350mm (Customized) |

3.Software Advantage

Self-developed Software

4.Contact Information

Phone NO./ Whatsapp:+1(408)590-8267

Website:https://szswesion.com/

Reviews

There are no reviews yet.