Skip to content

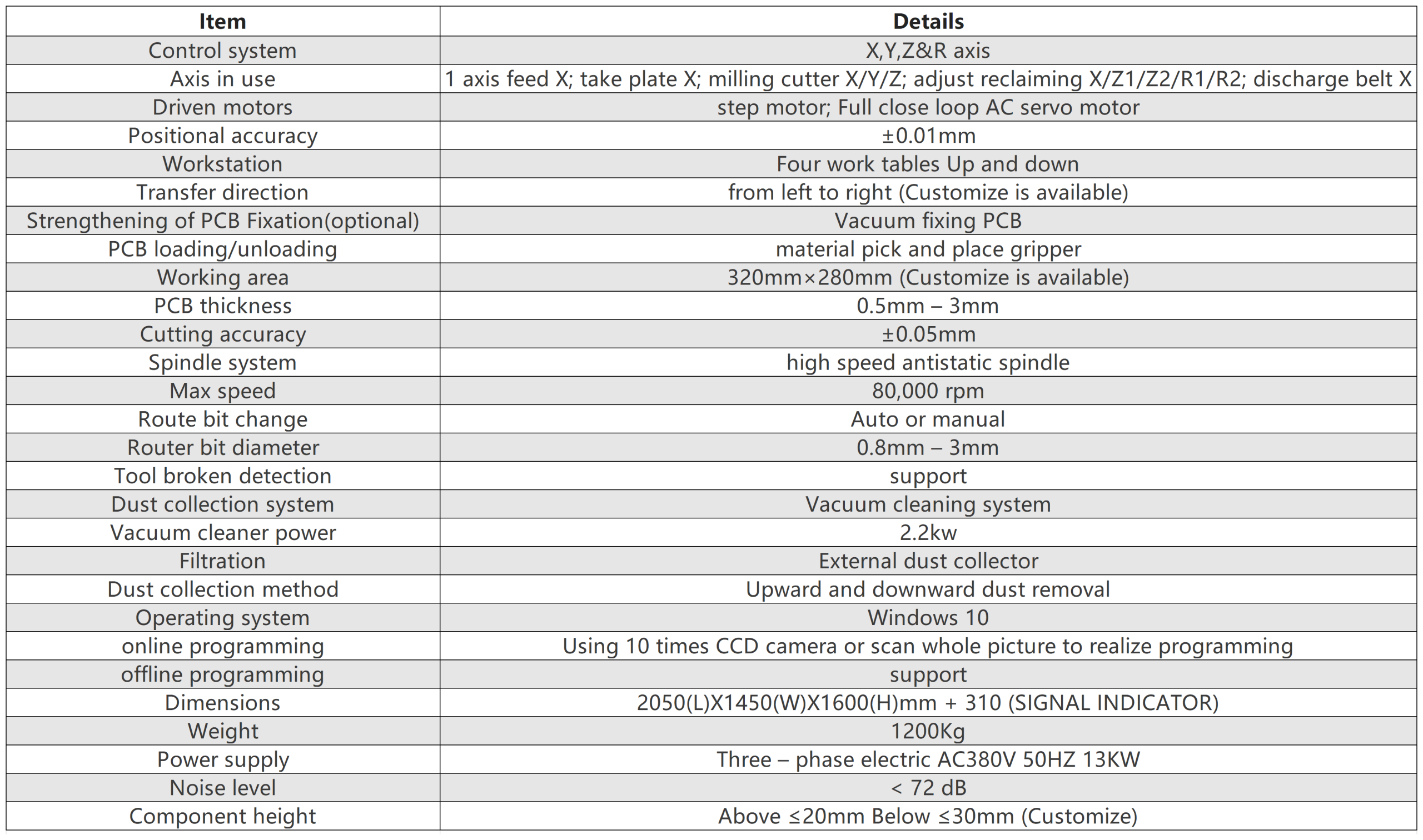

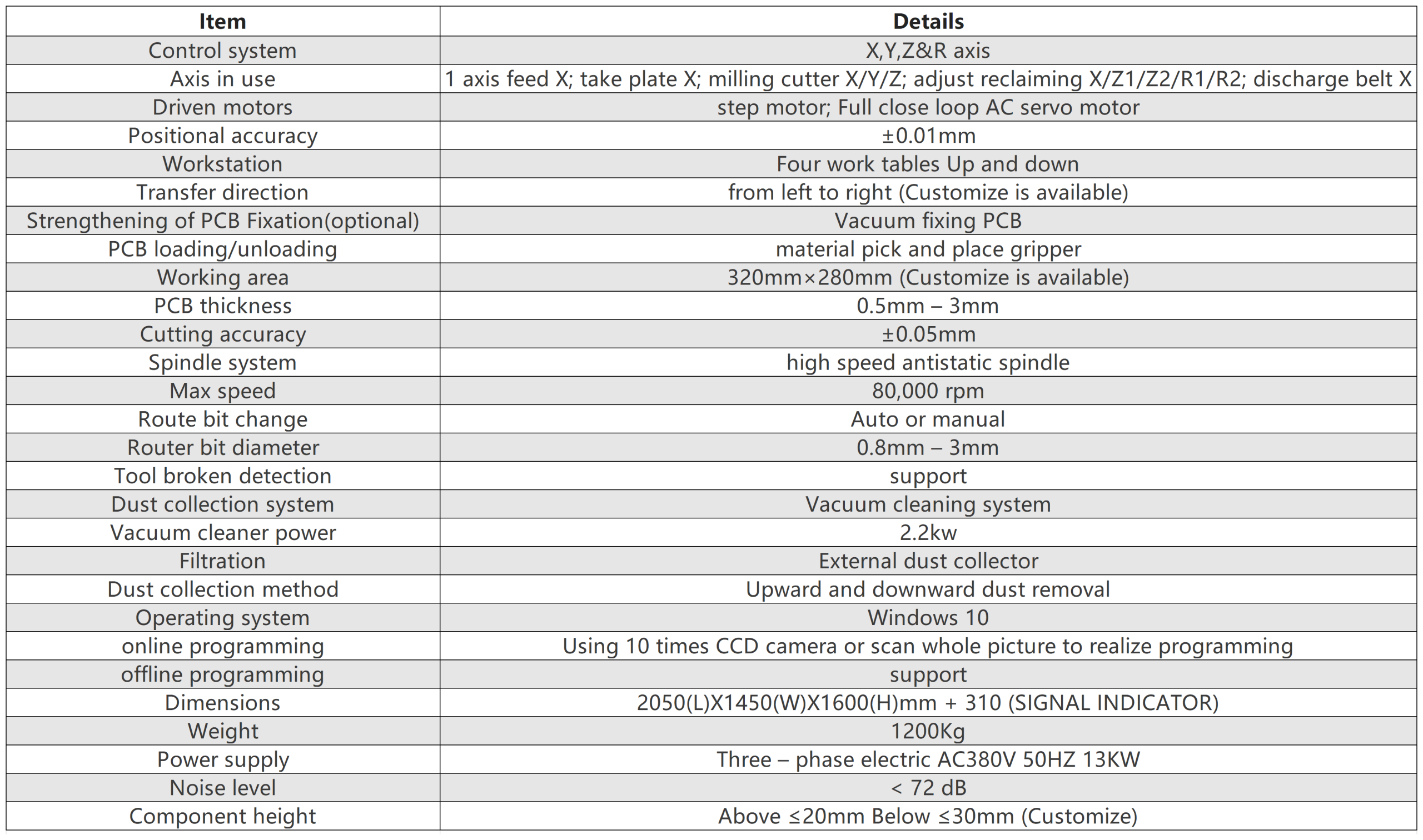

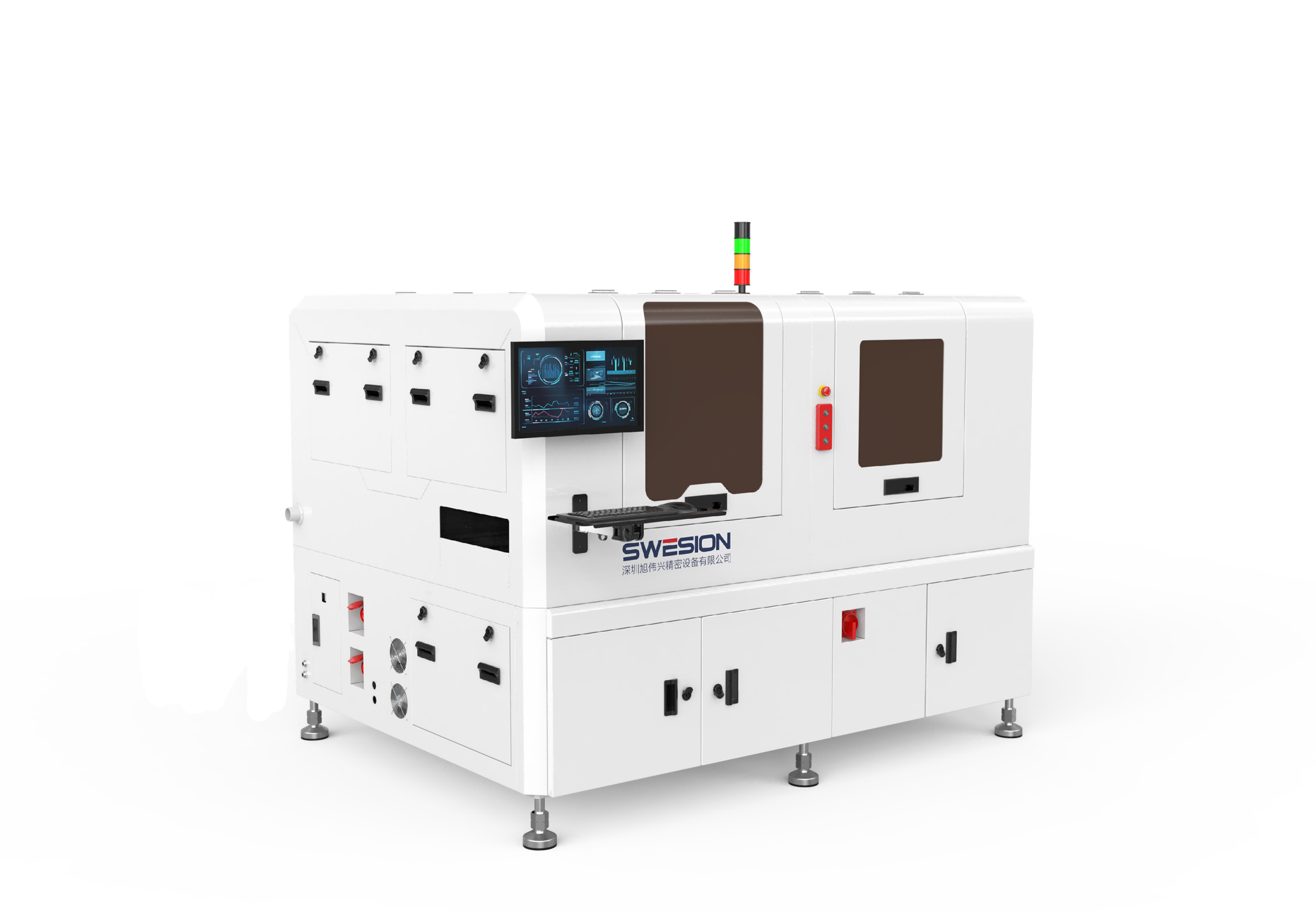

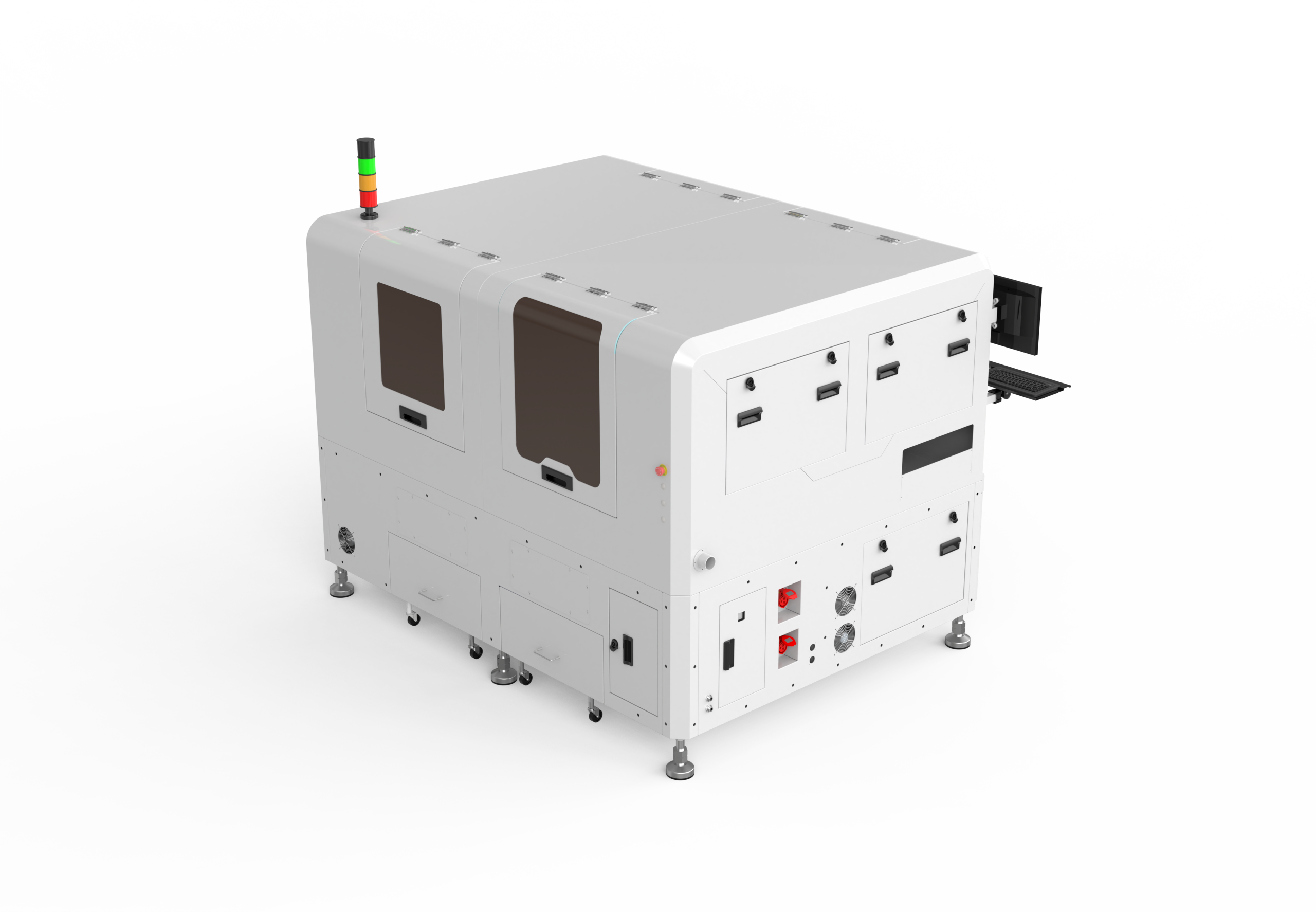

S500 High Efficient Multi-function PCB Separator

- Two spindles

- Four working tables

- ESD Certified spindle

- Tool life and status monitor

- High speed auto tray system

- Automatic router-bit exchange

- Auto scan QR code (optional)

- Up/down vacuum cleaner mode

- Auto picking PCB, Depanel PCB, and accurately place PCBA in tray

- Vacuum assisted fixing PCB (optional)

- Auto CCD detection of cutting position (optional)

- Multi-function offline programming system

- Suitable for high frequency production line change, solved the problem of long time line changing in depaneling machine industry.

S500 High Efficient Multi-function PCB Separator Depaneling Machine

- S500 is a high-end intelligent precision depaneling equipment that can be fully adapted to various PCBA products. After the panel enters the equipment, operations such as picking/placing boards, depaneling, discarding waste, loading finished products into Trays, stacking Trays, or directly feeding into FCT testing are carried out, achieving full-process automation.

- The linear motor control system enables direct drive between the magnet and the mover, eliminating various errors caused by intermediate links and ensuring high positioning accuracy. By adopting flux vector control and vector control technologies, it guarantees high-precision micro-feeding and higher sensitivity control.

- When the cutting tool reaches its set cutting life parameters or breaks, the system will automatically replace it with a new tool in the shortest time and quickly resume production, thus greatly improving production efficiency. Whenever a cutting task is completed, the system will automatically check the status of the cutting tool. If a tool breakage occurs, the system will automatically change the tool.

- The software process is extremely simple, allowing operators to get started quickly. Based on the visualized programming of scanned images, what you see is what you get, greatly reducing programming errors by operators during cutting and improving programming efficiency. It can be connected to the MIS system to enhance the level of management informatization.

- The dual-worktable allows the picking/placing and cutting to be interleaved and synchronized. From raw material input to finished product output, full-process automation is achieved without manual operation, effectively improving production safety and efficiency, saving labor, thus reducing production costs and improving production quality. The high-speed picking and placing system is inspired by chip mounters and is a patent of our company. It can accurately, effectively and safely place the cut finished products into TRAYs in an orderly manner. It realizes unmanned cutting for products in the current depaneling industry, such as chips, module crystals, main mobile phone boards and sub-mobile phone boards that require precise cutting. Customers of this picking and placing system can customize a multi-head picking and placing system according to their production needs.

Cutting Edge Inspection (Optional)

The products will be put in the fixture after cutting, the camera comes over the fixture to measure the accuracy of the cutting point. CCD will check the cutting edge, then system recorded data. Can dock with MES, put the NG product onto the NG Belt.

Reviews

There are no reviews yet.