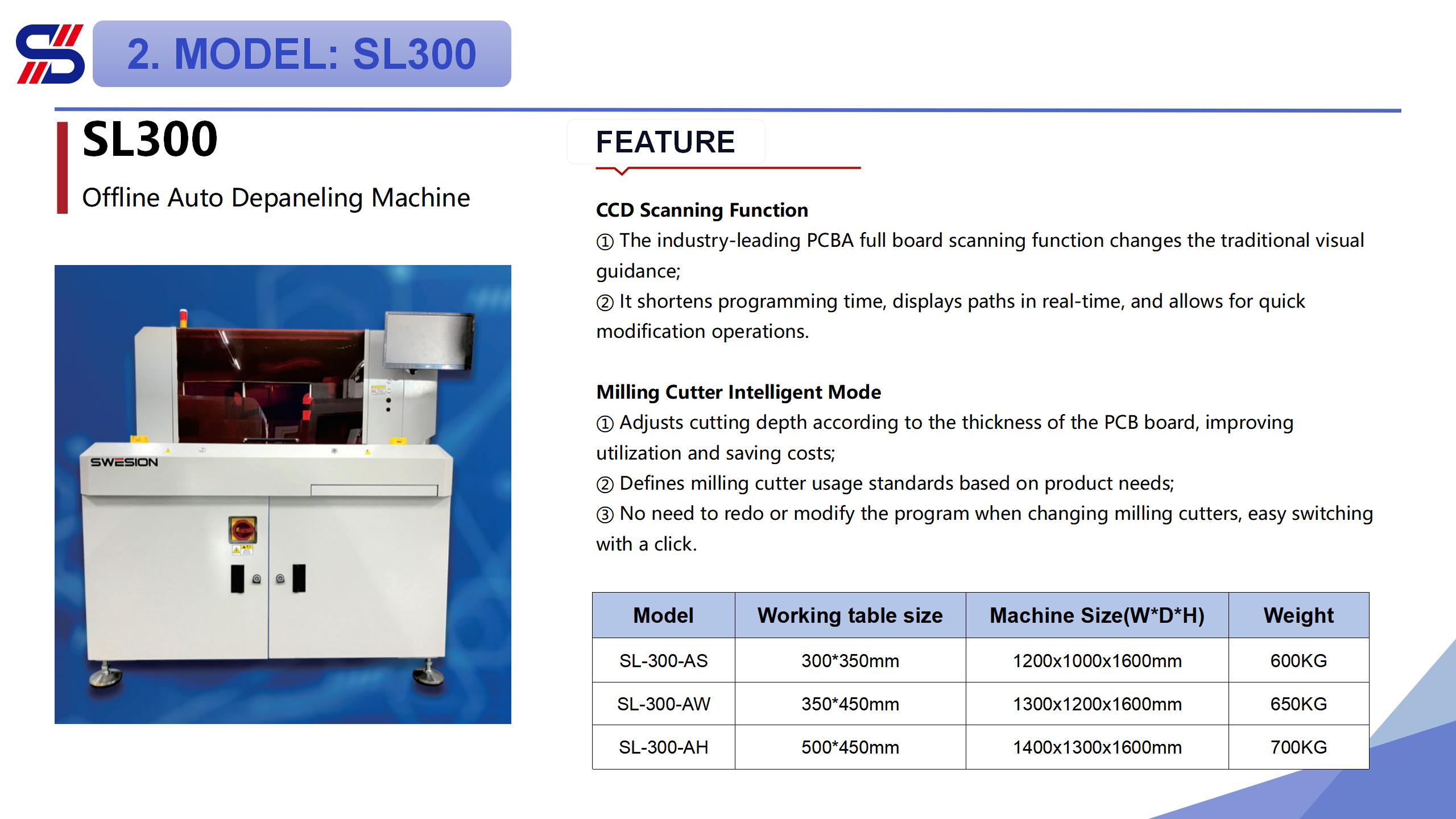

SL300 Offline Depaneling Machine

SWESION SL300 Offline Automatic PCB Depaneling Machine

1. Function

CCD Scanning Function

① The industry-leading PCBA full board scanning function changes the traditional visual guidance;

② It shortens programming time, displays paths in real-time, and allows for quick modification operations.

Milling Cutter Intelligent Mode

① Adjusts cutting depth according to the thickness of the PCB board, improving utilization and saving costs;

② Defines milling cutter usage standards based on product needs;

③ No need to redo or modify the program when changing milling cutters, easy switching with a click.

Achieve Automatic Cutting

① The cutting program is combined with production model and quantity, based on PMC planning production;

② Avoids premature production and unclear capacity;

③ Achieves separation between man and machine.

Operation Interface Mode

① Automatic detection function at startup;

② Graphical production and processing data, what you see is what you get;

③ Can learn processing data through CCD.

Full Process Control Run Error Monitoring

① Real-time recording of identification point errors during the cutting process;

② Real-time recording of motion axis errors;

③ Error values can be set according to product requirements.

Industrial 4.0 – MES System

① Automatic server data upload and retrieval;

② Upload machine and production data;

③ Real-time monitoring of equipment status.

2.Technical Parameters

| Model | Working table size | Machine Size(W*D*H) | Weight |

| SL-300-AS | 300*350mm | 1200x1000x1600mm | 600KG |

| SL-300-AW | 350*450mm | 1300x1200x1600mm | 650KG |

| SL-300-AH | 500*450mm | 1400x1300x1600mm | 700KG |

| Item | Specification Parameters |

| Working Mode | Dual-table Offline Type |

| Working Table Size | 350*300(mm) |

| Operating System | Automatic |

| Cutting Function | Straight Lines, Arcs, Curves |

| Vision System | Color Image Search and Positioning |

| Machine Repeat Accuracy | ±0.02mm |

| Cutting Accuracy | ±0.05mm |

| PCB Thickness | 0.5mm~3mm |

| Milling Cutter Diameter | 0.8-3.0mm |

| Spindle Speed | German SycoTec Spindle, Max 60000rpm |

| X/Y/Z Axis Drive Method | AC Servo Motor |

| X/Y Axis Cutting Speed | 0-100mm/s |

| Control System | PC System |

| Operating System | Win10 |

| Programming Method | Vision Point Alignment |

| Alarm Indication (Tri-color Light) | Yes |

| Alarm Fault Detection | Yes |

| Password Protection | Yes |

| Safety Door | Yes |

| Milling Cutter Change | Automatic 3 Cutters |

| Milling Cutter Segment Cutting | Supported |

| Tool Life and Status Monitoring | Supported |

| Automatic Detection and Monitoring | |

| PCB Positioning and Adjustment Method | Dedicated Fixture Positioning |

| PCB Enhanced Fixing | Dedicated Fixture Positioning |

| Troubleshooting | Automatic Alarm + Manual Maintenance |

| Equipment Air Supply | Clean Compressed Air |

| Compressed Air Pressure | 0.5~0.7MPa |

| Operating Temperature Range | 10~35°C |

| Main Machine Voltage | AC380V, 50Hz |

| Main Machine Power | 1500W |

| Air Supply Pressure | 0.5Mpa |

| Machine Dimensions | 1200(L)*1000(W)*1600(H)mm |

| Dust Collection Method | Upward and Downward Dust Removal |

| Filtration | External Dust Collection Box |

| Dust Collector Voltage | AC380V, 50Hz |

| Dust Collector Power | 5HP, 3.75KW |

| Dust Collector Dimensions | 680(L)*650(W)*1550(H)mm |

3.Software Advantage

Self-developed Software

Strong pertinence: Our company will tailor a suitable software program according to customers requirements. The development of the software has undergone careful structural analysis, our technical staff’s excellent program design ideas and scientific research mode into the software analysis, further improve the software scientific research and practical value, improve efficiency.

Easy to use: The software is written entirely according to the specific program of the product, customers easily operate the control software, reduce the cost of training and learning.

Provide our best service: Self-developed software is written by our company’s R&D team, after-sales service is more guaranteed.

Off-line programming, improve program editing efficiency.

Can dock MES system, improve the level of informatization management.

Reviews

There are no reviews yet.